If we want to reduce our dependence on fossil fuels, alternative plastics made from plants like hemp offer immense promise. These bioplastics are the topic of this week’s podcast.

First, our host Matt begins the Ministry of Hemp podcast with a word about our new Best CBD Pre-Rolls 2020 article. It’s full of great info pertaining to pre-rolled CBD cigarettes and hemp joints, which a lot of you have been asking about lately.

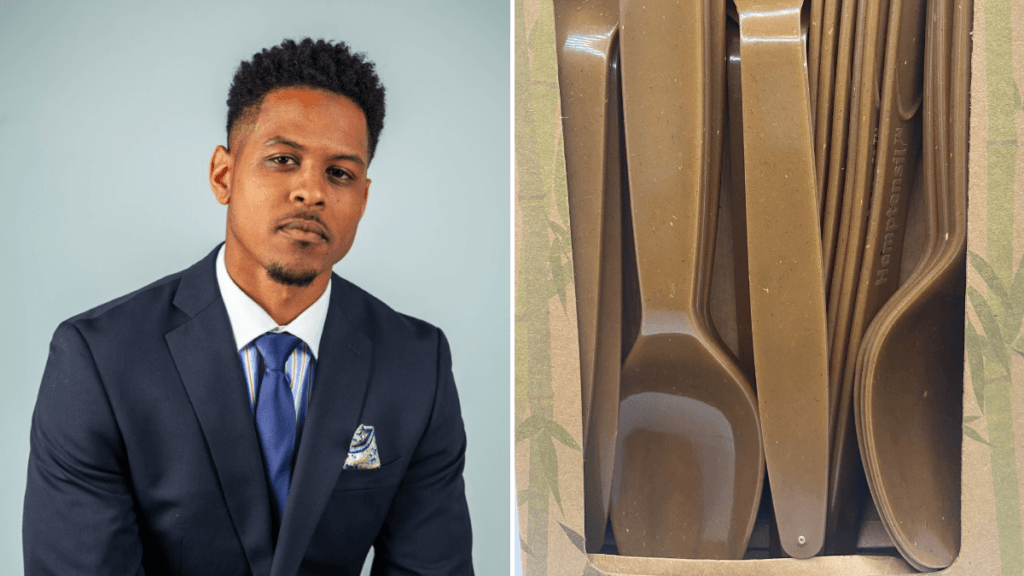

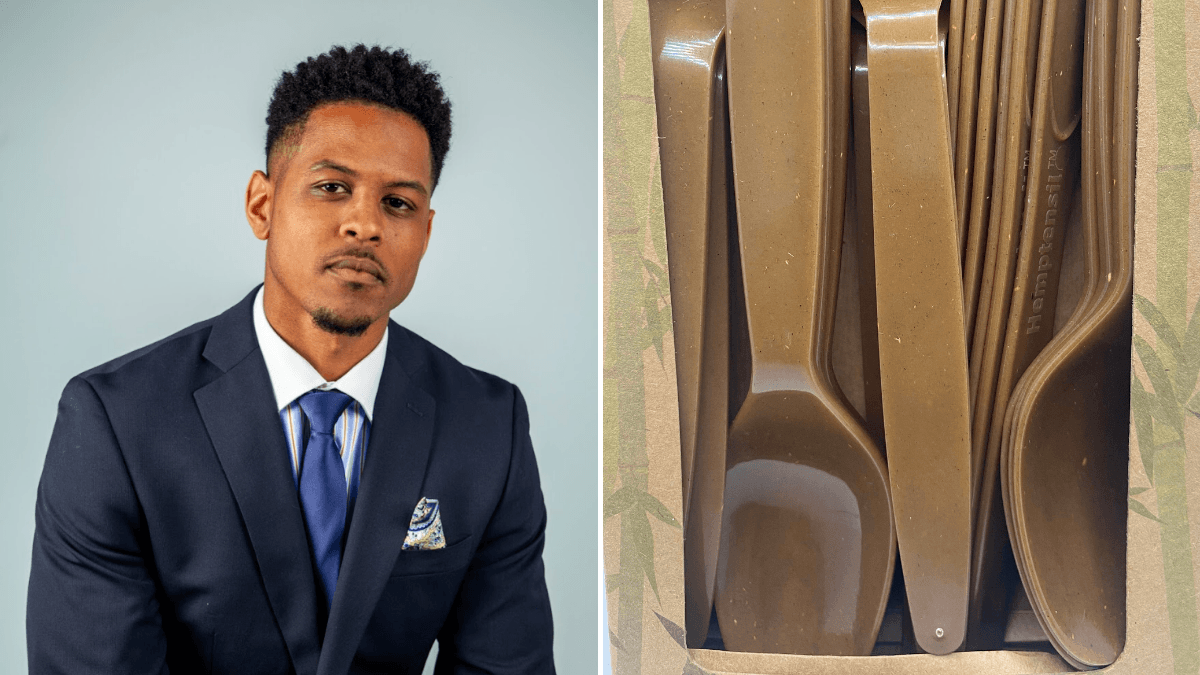

In the main conversation, Matt talks with Jordan Hinshaw, CEO of GreenTek Packaging. GreenTek’s misson is to replace everyday plastics with eco-friendly hemp plastic. The two talk about the benefits of not just hemp plastics but pairing them with other bioplastics too. They compare hemp and regular plastic in both strength, applications, and sustainability. Plus they discuss Greentek’s latest venture, Hemptensils which they hope to become a responsible replacement for single-use plastic silverware.

The Son of Major Leaguer George Hinshaw and a bilingual Los Angeles teacher/principal, Jordan developed a unique perspective on American Exceptionalism in the diverse city of Long Beach, CA. Having spent the early part of his twenties living and working in 20 states, Mexico, Canada, and briefly in Japan, he grew a clear understanding of the impact of climate change and plastic waste on the environment.

Idolizing the work of William H. Deming, Jordan’s belief in the future strength of the American economy being based on domestic manufacturing and renewable resources has guided his work towards innovations in industrial hemp. Following stints with both manufacturing and fulfillment companies whose supply chains were entrenched overseas, Jordan, along with a team of industry resources engineers andadvisors, established GreenTek in 2019. Now, they work to grow its offerings of eco-friendly packaging and housewares using domestic hemp and other plant feedstocks.

This episode of the Ministry of Hemp podcast is brought to you by Canvas 1839.

This episode of the Ministry of Hemp podcast is brought to you by Canvas 1839.

This episode is brought to you with help from our partners at Canvas 1839. This Austin, TX brand creates high quality CBD oil and CBD topicals using Colorado-grown, full-spectrum hemp extract. They develop their great products with the help of their chief science officer, Dr. Kyle Hammerick, a Stanford graduate.

We’re big fans of Canvas 1839 products and think you should try them too. And right now you can get 15% off your order just for being a listener to this show. Head to canvasrelief.com and use the code friend15 and you get 15% off your purchase. Thanks again, Canvas, for making this episode possible.

Send us your hemp questions and you might hear them answered on one of our Hemp Q&A episodes. Send your written questions to us on Twitter, Facebook, [email protected], or call us and leave a message at 402-819-6417. Keep in mind, this phone number is for hemp questions only and any other inquiries for the Ministry of Hemp should be sent to [email protected]

Be sure to subscribe to the Ministry of Hemp podcast on Spotify, Apple Podcasts, Podbay, Stitcher, Pocketcasts, Google Play or your favorite podcast app. If you like what your hear leave us a review or star rating. It’s a quick and easy way to help get this show to others looking for Hemp information and please, share this episode on your own social media!

If you believe hemp can change the world then help us spread the word! Become a Ministry of Hemp Insider when you donate any amount on our Patreon page!

You’ll be the first to hear about everything going on with our special newsletter plus exclusive Patron content including blogs, podcast extras, and more. Visit the Ministry of Hemp on Patreon and become an Insider now!

Jordan Hinshaw, CEO of GreenTek Packaging and creator of Hemptensils hemp utensils, joined the Ministry of Hemp podcast to discuss the promise and challenges of plant-based bioplastics.

Jordan Hinshaw, CEO of GreenTek Packaging and creator of Hemptensils hemp utensils, joined the Ministry of Hemp podcast to discuss the promise and challenges of plant-based bioplastics.

Below you’ll find the complete transcript of episode 55 of the Ministry of Hemp podcast, “CBD Testing & Stopping Bad CBD Oil”:

Matt Baum:

I’m Matt Baum, and this is the Ministry of Hemp Podcast brought to you by Ministryofhemp.com, America’s leading advocate for hemp and hemp education.

Matt Baum:

(singing)

Matt Baum:

Today on the show, we’re going to talk about hemp plastics. What are we really talking about, when we talk about hemp plastic? Let’s be honest, we’re talking about garbage, because plastic makes up not only the bulk of our garbage that we throw away, but it also sticks around longer than just about anything we throw away. Today on the show, I’m going to talk to a guy named Jordan Hinshaw. He’s the CEO of GreenTek Plastics. He is working on incorporating hemp plastic, into some very simple every day things that we use, single use plastics like containers and utensils. It’s an awesome conversation. This is the kind of guy that’s really going to change things, and I’m so excited for you to hear from him.

Matt Baum:

But before we get into that, I want to let you know that, we are once again partnered with Canvas 1839. They’re centered out of Austin, Texas they’re buddies of ours, and they are a fantastic CBD brand. You guys are constantly hitting us up and asking us, “Who can I trust? Who should I buy from?” Canvas is one of those companies that is doing it right, and we are super proud to partner with them. Later on the show, I’m going to tell you how you can get 15% off your first order from Canvasrelief.com. Huge thanks to canvas for partnering with us.

Matt Baum:

Before we get into the interview real quick, a lot of people have been contacting both the site and me, asking about pre-rolls, about smokable hemp. We’ve got a fantastic article up at Ministryofhemp.com right now. It’s all about the companies that are doing it right, from growing their hemp, to drying it, to putting it into their pre-roll, so you know exactly what you’re getting, and exactly what it’s supposed to be doing. Now, we’re not going to tell you that smoking is healthier. There’s dangers to smoking. Yes. If you’re inhaling smoke, you’re doing something that is not great for your lungs. But, if you’re doing it in limited amounts, to help with pain, appetite, anxiety, things that CBD really can help, there are very quick benefits to smoking hemp.

Matt Baum:

But, if you are going to smoke him, of course, we want you to do it with caution and in moderation. I’ve linked this article in the show notes for this episode. I’ve tried a few myself and I have to say, I really like smokable hemp, but again, only in moderation.

Matt Baum:

My conversation today is with Jordan Hinshaw. He’s the CEO of GreenTek Packaging, and Jordan is awesome. [inaudible 00:02:48] here he came up in the cannabis industry, and saw a real chance for hemp to become a plastic substitute, that could literally change the world. GreenTek is a manufacturing company out of the South Bay in Long Beach. They emphasize community improvement and sustainable economics. You’re going to hear him talk about responsibility before profit. I cannot stress how important and cool their mission is. This is my conversation with Jordan Hinshaw of GreenTek Packaging.

Matt Baum:

Jordan, before we get into it, why don’t you tell me what makes a guy like you decide, “Hey, I want to open a company that not only is dealing with hemp in a time where it’s still pretty wild west and scary, but I want to take on the plastics company, and show people that we can make the same stuff out of hemp.” Where did this come from? How does this start?

Jordan Hinshaw:

Yeah, no. It was kind of organic, no pun intended. The idea was floating around in Long Beach and in the cannabis space for some time, that you have all this raw material that’s not being used, and new advances in technology. So, I just wanted to be part of the forefront of that push, and saw it as purpose over profits. Coming out of my previous career, where I was well-paid for what I was doing and enjoyed it, but just didn’t feel like I was making an impact in a larger industrial way.

Jordan Hinshaw:

Luckily, I had the background of in engineering. I was at Cal Poly alumni, where I studied mechanical engineering, and Cal State, East Bay alumni, where I was doing industrial engineering studies in the off seasons on their quarter system, before that evaporated. So, I just felt like it was a next point for my skillsets and my interests.

Matt Baum:

So, what drew you specifically to the cannabis? Were you working in that? Cannabis obviously has been legal in California for quite a while, or did you just notice like, “Hey, there’s a real business here and a real opportunity that people aren’t seizing on.” Was it just that simple?

Jordan Hinshaw:

A bit of both. So, I’ve been a well integrated. Like you said, California has been legal for some time in the cannabis space. I myself, I’m a member of the Long Beach Collective Association, as is our company, and I had done some work with… I’ve worked through the supply chain of cannabis a bit, more on the logistics side, fulfillment, even down to being able to go to the fields and see how they operate, and do that side of the business since I was… I’m 30 now, so it’s about a decade ago when that started.

Matt Baum:

Wow.

Jordan Hinshaw:

It was just kind of the tinglings of someone who’s interested in that space, and understands and respects that it’s more than just psychoactives and good times. There’s actual industry and innovation going on.

Matt Baum:

Tell me about GreenTek. How did it start? Right now, you’re moving into the utensils, which is how I found you. I saw a press release and I was like, “This is freaking amazing and exactly the kind of stuff we need to be doing with hemp.” How did GreenTek get started? What was the first products?

Jordan Hinshaw:

The first products were all based on packaging for the cannabis industry. We were prototyping a ton of containers that had a balance of like rigid aspects with the base, and some elastomers that we were going to make them airtight, and try to offer something that was industrially compostable and made from plant based matter. We were courting some rather large pre-roll companies, like flower companies that were doing units at 50,000 or 100,000 per month, where we would justify some custom materials that were a bit over in the luxury range of pricing, but were environmentally much more beneficial.

Matt Baum:

Yeah, you’re making a statement, definitely. If you’re going to grow this stuff right, and you’re going to talk about how important it is to farm it, and do it the right way, you may as well package it the right way too, right?

Jordan Hinshaw:

Exactly. That’s all feedback from the consumer base. That’s all based on how people in general are moving in that direction. The companies don’t want to be too far behind it, so they’re trying to match solutions with revenue.

Matt Baum:

So, what was the most difficult part? Like when you guys started this and you decided, “Okay, we want to move into hemp plastics and whatnot,” we call it hemp plastics, but there’s no petroleum in it. What was the hardest part in developing that kind of stuff, and also getting it to the consumer, who’s going to buy it and package their stuff? When I say the consumer, the companies. Was it difficult to sell them on the idea that like, “Hey, this is going to be a little more expensive, but look, it does the same job. Not just that, you can throw this away and not feel guilty about it.” Was that all it took to sell them on it?

Jordan Hinshaw:

Right. So yeah, if you were able to make it as concise and well put as you did, absolutely. It’s a massive undertaking.

Matt Baum:

If you guys are hiring, let me know. This sounds cool.

Jordan Hinshaw:

Very well done, right? It was a massive undertaking, and a supply chain management challenge where, you got new infrastructures, new machinery that’s being placed around the nation, farmers that are just getting into their swing of things in terms of production and specifics of how it comes out. So, it’s working with those groups collectively, understanding our own capabilities, to be able to offer pricing that is measurable to the value add in their operations.

Matt Baum:

Right, right.

Jordan Hinshaw:

We’ve had some swings and misses for sure. We’ve had some really big players that came to us and asked us to work with them, and then kind of got an idea where the pricing was, and was like, “Well, we’re going to hold off a little bit longer.” But, we’ve also had a lot of smaller businesses that are much closer to their consumer, that are much more quick to say, “We understand the intrinsic value of what you’re doing here,” because the externalities of us continuing to make plastics are outweighing the small pennies that we’re saving by using them.

Matt Baum:

Absolutely. Let me ask you, when you said you had like some bigger companies that came in, and they looked at the pricing, and obviously they’re going off bottom line in a case like that, is it just a matter of catching up technology-wise to bring that price down? Or, is it a matter of more people growing hemp? Is it a matter of more processing, better processing? What do you think pushes that price point down to a point where you can say something like, “Hey McDonald’s or Hey, Walmart…” Don’t get me wrong. I’m a big fan of health food stores and the whole foods and whatnot, but they’re not going to change the world at the price point they’re selling food at. We’re going to change the world by getting this stuff in frigging Walmart, you know?

Jordan Hinshaw:

Right.

Matt Baum:

What do you see as the biggest hurdle to getting that price down? What do you think?

Jordan Hinshaw:

Right. I think it’s mainly the second by comparison of those aspects. Scale really is a huge thing, and you have to walk that up. It’s speculative to guess that everything is going to go perfectly well when you go from selling 100,000 units to 100 million units.

Matt Baum:

Right.

Jordan Hinshaw:

So, there’s a brick by brick aspect of building the industry, where you want traction to grow in an organic manner, to a point where you can be confident to say, “Hey, look McDonald’s, we have this proven process here. Delivering at this scale would allow us to be price competitive within 10 or 20%,” and have them say, “Yeah, yeah, we see the work you’ve done. We believe in that enough to invest, and make that switch over, without having to deal with all of kinks and issues that any expanding business would deal with.”

Matt Baum:

Sure.

Jordan Hinshaw:

On the other side, yes, supplies. There’s actually a glut of a material right now. I think last year, industrial hemp acreage increased to about 125,000 acres in the nation, up from the tens of thousands a few years back. 60% plus of that didn’t have scheduled offtake. So, you’ve got a lot of material out there, that’s going to actually push down the price the more of it you use. But, you just need to be organized supply chain wise, where your processing is within range of where you’re doing it, and you’re able to coordinate all the pricing, so that you can guarantee that, “Hey McDonald’s, you will have it, as we say it will be,” for example.

Matt Baum:

Let me ask you, as far as… I was reading the press cue you guys have coming out, and it sounds like this utensil thing, people are pretty excited about this. I thought it was cool as hell. But, take me through it. We don’t have to do the hardcore science or anything, but take me through the process, like, the hemp comes in and it ends up as plastic. How does that work? That just sounds nuts.

Jordan Hinshaw:

Yeah, pretty cool stuff. Essentially, anytime you work with the stalks of the plant, the lignocellulose, you have an opportunity to extract the sugars from it, which build the starches. In that process, you’re creating the same polymers that are used in petroleum plastic. It’s when they make it from oil or in a large amount of cases, natural gas.

Matt Baum:

Literally the same polymers? Like no difference? That’s-

Jordan Hinshaw:

Similar. There are differences, depending on the formulation that you use. There’s mixes of sugarcane, of cornstarch, of different materials that have different properties, and they tend to… You tend to trade off between sturdiness or toughness versus flexibility, which has been a pretty big challenge for a lot of a lot of our products. Where, the more hemp fiber you have in it, the stronger and lighter weight it is by density, but oftentimes it doesn’t have that type of like pop-pop capability that people are often used to.

Matt Baum:

Basically, you’re not using the leaves, you’re using the stems, and you’re de-coordinating them, if you will.

Jordan Hinshaw:

Decorticating. Yes, that’s-

Matt Baum:

Decorticating, got it.

Jordan Hinshaw:

… That’s a word if you type into Word, it will always have a little red squiggly underneath it.

Matt Baum:

Yeah, yeah. I even practiced saying it, and I still got it wrong. That’s great. But from that point, it comes in as like little pellets basically, that you’re turning it into? Then those pellets, are you literally melting them into forms from there?

Jordan Hinshaw:

Right. That’s the process, whether by injection or extrusion, in some cases some compression molding and thermoforming, to heat it to 190 degrees, 210, 240, and press it into an extremely heavy tooling. In some cases, 1400 pound steel item that is water cooled around it, so that once it goes in, it’s able to pop out as the perfect shape of what you made it, designed to be.

Matt Baum:

Just like you would with plastic basically, but no petroleum.

Jordan Hinshaw:

Yeah, yeah, a very similar process. Absolutely. The only difference obviously is in processing temperatures, and cycle times, and aspects that have to do with how the material wears on the tooling. So, it’s not as transferable, where in a lot of cases, the material dictates how you actually build the tooling. Ours are unique to these types of materials.

Matt Baum:

Let me ask you differences between this hemp plastic and petroleum plastic. Is it a matter of like strength or transparency? What are the major differences? Are there pros, cons? Let’s just take the ecology side out of it for a minute, and just discuss raw pros and cons of stability, what it looks like, stuff like that.

Jordan Hinshaw:

Right. So, the material we’ve been working with has a really natural color to it, that natural hemp brown. So, transparent items have not been… We’ve not been able to achieve that aspect. But, you can always add color additives that are nontoxic, if you so choose, to make it black or brown or blue, whatever other colors that are optional.

Matt Baum:

Sure. So, clear is not really an option yet.

Jordan Hinshaw:

Not in hemp, no. Obviously, the biomass itself has that natural tinge, and so you’d be hard pressed to try to make that-

Matt Baum:

It’s green, right? What are you going to do?

Jordan Hinshaw:

Yeah, exactly. But luckily, it’s a nice hazelnut color, hazelnut hemp.

Matt Baum:

Cool.

Jordan Hinshaw:

So, it’s kind of got a nice visual aesthetic to it. So, we’re not too ashamed of that.

Matt Baum:

Let’s take a quick break, to talk about our partner this week, Canvas 1839, centered out of Austin, Texas, which also happens to be the de facto home of Ministry of Hemp, because Kit lives there. Canvas strives to make products with the highest efficacy based on proprietary science, with the help of their Chief Science Officer and Stanford grad. Dr. Kyle Hammerick’s pioneering work in nanoscale biology. Canvas currently offers a relief oil that is crafted with Colorado grown, full spectrum hemp extract, grown under organic practices to support your wellbeing in mind and body.

Matt Baum:

Each one ounce bottle contains 300 milligrams of CBD, which is 10 milligrams per dropper. Now, they sent me a bottle and I have to say, normally, 10 milligrams of CBD isn’t enough for me, but I’ve really been enjoying it. I’ve been taking the relief oil in the mornings with my coffee, and I feel like it brings me in for a soft landing, as I get to work. I’m focused and I’m awake, but the Canvas relief oil keeps me from my usual ADD morning coffee rush. It’s actually helped with some of the aches and pains that I’ve been dealing with, since I started boxing training again.

Matt Baum:

They also offer a luxurious relief cream that is specifically formulated for optimal transdermal penetration and absorption, which means, when you rub it on your skin, it actually goes into your skin. It leaves a very clean skin field with no residue whatsoever. There’s 500 milligrams of CBD in each two jar. My wife, who’s an aerobics instructor and owns a gym has been using it, and she loves it. It’s become a part of her post-workout shower regime. Canvas is a company that is just doing it right. That’s why we’re proud to partner with them. They know their farmers, they have third party lab results readily available. Right now, you can get 15% off your order, just for being a listener to this show. Head to Canvasrelief.com and use the code Friend15, and you get 15% off your purchase.

Matt Baum:

I would recommend their starter pack. That features the two products they sent me, the relief oil and the relief cream, and both are fantastic. That’s Friend15, all one word. Of course, I will have a link to Canvasrelief.com in the show notes, for this episode. Now, back to the show.

Jordan Hinshaw:

Besides that, obviously the heat implications, depending on product thickness, it’s designed to allow heat and bacteria to eat away at it.

Matt Baum:

Right.

Jordan Hinshaw:

So, while it holds up on a shelf just fine for years, if you do apply it to higher pressure, a higher heat environment, it’s going to start to soften in a way that actually no other plastic really does. We did some testing on some basic corn plastics, and they tend to break at a certain temperature change.

Matt Baum:

They get real brittle, right?

Jordan Hinshaw:

[crosstalk 00:19:16] shaped. Yeah, brittle. Whereas the hemp plastic, actually, it doesn’t get brittle, it gets really elastic. It’s really flexible.

Matt Baum:

Really?

Jordan Hinshaw:

Yeah. So, we were testing it out, we dumped it in boiling waters for a period of time. All we had to do was dip it back in cold water and it solidified right back into it’s shape, and we were able to bang it against the table.

Matt Baum:

That’s cool.

Jordan Hinshaw:

It was really interesting.

Matt Baum:

That’s cool. Do you think that’s a difference in sugar content of the corn versus the hemp basically?

Jordan Hinshaw:

Yeah. The content of the hemp itself, the nature of fibers, just their resilience lends towards that more flexibility under pressure, rather than just snapping overall.

Matt Baum:

Sure. So, what about raw strength of the product itself? How does that compare to like plastic? Is it stronger, the same, not quite as strong? What are we talking?

Jordan Hinshaw:

Rank well, as it’s stronger. There’s evidence there since the ’40s, where they were doing a Ford, if you’ve ever heard of that experiment, he was putting it in his-

Matt Baum:

Yeah, his car and stuff, right?

Jordan Hinshaw:

In the walls of his car, and taking hammers to it. That’s actually still been going on. I believe Mercedes, if not BMW, has a line of doors, their lining that’s more than carbon fiber, it’s hemp fiber.

Matt Baum:

Yeah. I just interviewed those guys actually a couple of weeks ago.

Jordan Hinshaw:

Very nice. Essentially, strength is never a trade off. You’re actually increasing your density. So, compared to most of the exact same weight, you’re going to have a stronger product for certain. The main differences are more chemical based where, there’s a lot of compatiblizers, additives and such that they add, that often have these toxins and stuff. Without getting too much into it, that can affect temperature and barrier properties, where they’re able to resist more caustic environments.

Matt Baum:

Right, right.

Jordan Hinshaw:

These are for your lunch at the break room.

Matt Baum:

Right. This is stuff that you want to disappear when you throw it away. You don’t want it to stick around forever.

Jordan Hinshaw:

Exactly.

Matt Baum:

Speaking of temperature, obviously plastic burns at a certain temperature, and it gives off all kinds of caustic fumes and stuff. What about hemp plastic? Does it burn the same? What happens when you apply fire to it?

Jordan Hinshaw:

Like you said, with little petroleum plastics, and it’s a great question, they do emit a lot of greenhouse gases as they burn up or break down. Carbon dioxide is released as a process of breaking down most… That’s when they say it’s carcinogenic, whatever. But, the hemp itself is more of a plant based matter. So, it has less of a negative impact in that way. But that being said, I have not actually set these on fire on purpose. So, I’ll have to add that to the list.

Matt Baum:

Would you be willing to burn something right now?

Jordan Hinshaw:

Right. You know what? That’s a great point.

Matt Baum:

I’m just curious. You start thinking about the ecology side, which I want to talk about next. Obviously, this stuff isn’t meant to be permanent. The idea is, this is temporary packaging for a cupcake, or your lunch, or something like that. What’s the difference if I take, let’s say a hemp packaging that is like a bag, for example, and I bury it next to a plastic bag in my backyard, or maybe I don’t even bury it, I sit them outside in my backyard. That plastic bag is going to be different thousands of years. How long… What happens to this hemp bag? How long does it take to break down?

Jordan Hinshaw:

In an aerobic environment like that, where it’s just sitting on top of the ground-

Matt Baum:

Right. Aerobic meaning air can get to it, right?

Jordan Hinshaw:

Sorry, say it again?

Matt Baum:

Aerobic meaning air can get to it more or less.

Jordan Hinshaw:

Right, right, right. You’re still going to be facing dozens of years, where the hemp plastic will hang around, because it’s actually more about the bacteria and the soil, like the environment itself, that’s allowing it to become a food source for, well I wouldn’t say fauna, but for the environment around it. So, what you’re really looking for is for it to be able to get back into the food chain, or the environment of soil or dirt or, and obviously ideally a compost. But, if it does get in those environments with ability to break down, then it could be as short as six months.

Matt Baum:

Wow.

Jordan Hinshaw:

How I see it evaporate.

Matt Baum:

That’s crazy.

Jordan Hinshaw:

The trade off there… Yeah, it’s pretty big. That’s why we’re really concentrated on pushing this element because, we understand that there’s a ton of politicians, a ton of legislation that is looking to solve all these problems of getting away from plastics, but that requires development of these composting centers, circular economies, and production of plant based materials.

Matt Baum:

So, I can compost. I compost on my backyard right now. I can compost this. If you send me something in hemp plastic, I can take it out, eat it, have a nice little meal and then throw the scraps, the vegetable scraps and the bag into my compost, and it’ll break down.

Jordan Hinshaw:

Yeah. About half of all the industrial composting centers, they do that on a pretty regular basis. I think it’s important that we try to move away from recycling.

Matt Baum:

Yeah.

Jordan Hinshaw:

Not move away from it necessarily, but look to materials that are going to provide some alternatives, just for the obvious reason that for one, a lot of recycling doesn’t get done. And then two, these plant based materials actually are not ideal for recycling. These are designed to be that type of degradable material. So, we’ve got some different experiments going on right now, we’ve got the B5511, which is an [inaudible 00:25:29] one, where they’re doing it in a backyard compost center. Then, there’s a few different methods that we’re testing out, so that we can really get a hard number on exactly how long they’ll take. But, that’s the idea. We really want to see higher quality compost going on, and we want to give them the feed stock that makes that possible.

Matt Baum:

And making a temporary product, like you said, that we don’t have to worry about. When you’re done with it, you don’t have to feel guilty. Speaking of which, let’s talk about the utensils. You guys have a big thing coming out right now. You just partnered with British Columbia. Can you name who it is yet, or is it still let’s keep it under wraps?

Jordan Hinshaw:

Well, we’ve already been under a distribution agreement with them, so it’s not necessarily a secret. It’s a company called Follow The Leader Distribution Company. They were really adamant about offering new eco-friendly solutions for packaging in that legal cannabis market there, and have since expanded. So, we were wanting to make sure that we sent them what they needed to that market there. Obviously, without overshooting, I’d say that the Canadians are in the advanced awareness state or acceptance state of the challenges of climate change, and are constantly looking to invest and find ways to bring those to fruition.

Jordan Hinshaw:

We’ve got a number of distributors that are spread out, and it just happens at two of them are in Canada, one there in BC, and a new one that we’re working on in Toronto. So, it’s no secret or anything, but it was encouraging to know that companies from all around the globe have been reaching out to us to see, “Hey, what can we do?” Which is just ironic in the sense that, we’re here in one of the top economies in the world, and these other countries are saying, “Hey, let’s-

Matt Baum:

Yeah, we like to make fun of Canada, like they’re our little brother, but they typically make us look pretty bad when it comes to stuff like climate science.

Jordan Hinshaw:

You got it.

Matt Baum:

It’s sad, unfortunately. Now, tell me about the utensils. How did you develop this? It’s like a fork, and a spork and a spoon, but they’re made of hemp plastic. It almost looks like they’re made out of wood, because of the color you said, that they have, and straws as well, hemp straws. Tell me they’re better than paper straws, because paper straws, they’re the worst.

Jordan Hinshaw:

Absolutely, yeah. The hemp straws are the big winner. We’re trying to get that prepared for a much larger scale launch because, we understand there’s just so many bars, restaurants, places of business, that are looking for an-

Matt Baum:

Yeah, absolutely, coffee shops.

Jordan Hinshaw:

… Alternative. In my mom’s generation, they were using paper straws, so it’s not a revolutionary thing to have them, and nobody liked them then either.

Matt Baum:

Yeah, they were garbage.

Jordan Hinshaw:

Yeah. The ideas, bamboo… I go to the store and cost-plus goods, and they’ve got bamboo straws that they’re selling for $1 a unit. We just knew that there’s got to be a middle ground there between the paper straws, which are doing a good thing and, and trying to reduce that. But using hemp as a feedstock, a material not neither a crop, a food crop nor forestry, rather than that paper. So, we’ve been experimenting with that for the last six weeks, and trying to get everything on point to break that the hemp straw out.

Matt Baum:

That’s so cool.

Jordan Hinshaw:

As far as the utensils, I’ve got a partner who helps with the CAD design, and try to engineer it based on material specs. Then, you get a large EDM machine out and start cutting steel. There’s steps and stages, but it’s been a fun process for sure.

Matt Baum:

My wife and I, we have those metal straws you can buy, and that’s great, you’re not throwing away plastic. But, you are introducing more metal straws, that are also made with gnarly chemicals, and they’re to be around forever. Whereas like the bamboo straw, like you said, great idea, too expensive. It’s just too expensive. Bamboo is an amazing plant, but it doesn’t grow as fast as hemp. It’s not as cheap and easy to grow. The same thing with reusable bags, and water bottles and stuff like that, it’s great, and we should be doing that stuff. But, we’re also creating an army of bags and water bottles, that will be around for the next 100,000 years, you know?

Jordan Hinshaw:

Yeah.

Matt Baum:

So, what do you think the future is for you guys? Where do you go from here? What’s next?

Jordan Hinshaw:

It’s really interesting that you say that. I think with the reusable bags, there’s some stat. You’ve got to use them at least 28 times for them to even justify, because of the additional industrial waste or impact from making them. A lot of steel, the metals are no different in that way. That’s the idea is that, we believe that hemp itself is that carbon neutral solution. So, obviously as it grows, especially purpose grown for fiber, it absorbs more carbon from the atmosphere than any other crop.

Matt Baum:

Absolutely.

Jordan Hinshaw:

So, what you’re finding is that, by growing it and then using it in manufacturing processes, which often in bioplastics already have lower emissions, you’re striking basically a sustainable supply chain. So, that’s kind of what we’re focused on. We’re trying to say, “Listen, it’s not just about the actual bioplastic result, and the fact that it’s better at the end of life. It’s about the entire chain, and how we’re using our domestic economy to its fullest, our own agricultural resources to develop products, innovate in those products, and become more independent as a nation, creating jobs, all that.” So, that’s our focus. We’ve got some different pilot programs for some technology to be developed, that’s going to make it as cost competitive as possible. But, we just understand that it’s an invigorating leg up for America.

Matt Baum:

Definitely, definitely.

Jordan Hinshaw:

So, that’s kind of where we see ourselves going.

Matt Baum:

How far away am I from hemp plastic bags in my grocery store? What am I talking 5 years, 15 years? What do you think?

Jordan Hinshaw:

Certainly within five years, I think you could see that. I know there are some groups that are already trying to develop some blown film options with that. Again, I think it’s going to be a matter of which companies buy-in, to lock in those kinds of purchase orders, and justify those supply chains first. But, I think within the next five years, you’re going to see some options that are those lines. If it took 10, then it was a policy problem. It was something to do with-

Matt Baum:

Absolutely.

Jordan Hinshaw:

… Our nation not invigorating and pushing for these types of things. But, there’s some cool stuff coming down the wire.

Matt Baum:

That’s cool to hear you say that though, because just to hear someone that’s in the industry say like, “Yeah, we can do this, and it is going to take a few years, but it’s not going to take 10 years. We’re learning, we’re kicking ass here, and it’s more a matter of don’t hold us back, than it is, we need to come up with brand new technology and the future we’re talking about.” I’m really happy to hear you say that. Let me ask you, what is the one plastic product that you are most excited about replacing with hemp plastics, that you think makes the biggest difference in the world?

Jordan Hinshaw:

The biggest difference in the world? Well, let’s start from top down. If you look at 50% of all plastics that are made, those are usually single use. So, you’re really talking about these subscription food boxes, these take to go boxes and take out.

Matt Baum:

Yes.

Jordan Hinshaw:

You’re looking at things that are consumed in the pounds per day, per person, that really would impact the waste that’s gathering up in the middle of the Pacific Ocean right now. Some of the most common ones are our medical containers, pharmaceuticals and such, that really could be made from bioplastic materials, and are shipping out again all around the world. Being here in Long Beach, when I go to the beach, which I love my city, but it’s not one of the cleanest beaches by far.

Matt Baum:

Yeah, I’ve been there. I know what you mean.

Jordan Hinshaw:

That’s what you find.

Matt Baum:

Yeah. You find hypodermic needles and pill boxes and stuff, yeah, unfortunately.

Jordan Hinshaw:

Unfortunately. It doesn’t make me happy. But, those are some of the things that I think, if those were integrated from renewable resources, you’d have a real acknowledgeable impact in plastic waste.

Matt Baum:

Making a real change. You’re absolutely right. It’s that crap that we don’t think about, that we use every day, the container for your pills, the container your lunch came in, and stuff like that. How far off do you think we are from developing a clear plastic? Is that out of the question or is it just a matter of like, “Hey, we’ll figure it out. It’s coming.”

Jordan Hinshaw:

Again, it’s just material sources. When you’re talking about bioplastics in general, there’s a lot of options, from the material for tapioca all the way to sugarcane.

Matt Baum:

Right.

Jordan Hinshaw:

Now they’ve got some mycelium with mushrooms, and different options.

Matt Baum:

Yeah, that’s really cool too. They’re doing a lot of stuff there.

Jordan Hinshaw:

Yeah. We’ve been wanting to work with them for some time. They’re so overwhelmed with demand themselves, that you’ve got to go down there and knock on their door in-person.

Matt Baum:

I’m sure. That’s a good problem to have though. That means they’re busy. That means they’re kicking ass, hopefully.

Jordan Hinshaw:

Oh, yeah, yeah. It’s a product that people want, and it’s a classy product. It’s a really nice looking final product. But no, my point just being that, is that technology coming? Yes. Is it something in the immediate future? I don’t think so. If you choose to do it with some of the older materials, obviously bioplastics have been around for much longer than you’d imagine, when you don’t involve the hemp itself, you can find some clearer plastics. I think World Centric makes some clear bioplastics, although I’m not sure exactly what their formulation is, in terms of petrol, corn, whatever the balance may be.

Matt Baum:

But, you’re saying there’s no reason why there couldn’t be a combination of two things. You have your hemp plastic thing on the bottom, and then on top, maybe you have a mycelium plastic or some other type of bioplastic.

Jordan Hinshaw:

Exactly, yeah. Again, it’s just going from, right now, I think 1% of all plastics are made from bio renewable resources. So, it’s going from that to an increase in margin, increase in part of the market, where you’re going to find those type of combinations and solutions are more prevalent.

Matt Baum:

I ask because I was a chef for a long time, and working in kitchens, clear plastics, we literally go through tons of that stuff. You’ve got to be able to see what’s in it. So, when you’re in a hurry, you open it up and there’s a bag of label that and you can see it’s perfectly good, we’ll just grab it and go. When that bag is empty, you can’t reuse it because the health code won’t even let you. That’s against the law. You have to throw that crap away. Every time I did it, it just felt gross. Every time you wrap something in cling wrap, every time you threw something in a freezer bag, and you thought it out and then you just throw it away, it’s perfectly good, it’s going to be around for the next 50,000 years, but you can’t use it again. That’s the kind of stuff that’s another single use plastics, if we can start to replace that.

Jordan Hinshaw:

That’s what the overarching… GreenTek Packaging, obviously we focus on the division, and manufacturing these products, developing them, and providing them to the market, but in reality, GreenTek Planet is like, “Well, let’s combine those different resources.” Like for example, with the cellophanes, you’ve got some seaweed aspects there, that are moving towards making these thinner, more clear or see-through materials. Those are going to be the type of advances that cover a lot of the more unseen or low weight solutions for the bags and the options that you’re talking about. I think that that’s really where the pendulum is going to need to swing, to see those turtle suffocating items, not end up in the cycle. Again, I’m not sure to what level or what advancement specifically is going to turn that tide, but I know that we are a part of the group that’s pushing for that.

Jordan Hinshaw:

So, obviously it’s been a great opportunity to chat with you, and I’m thankful that we did connect. We’ve been doing a lot in terms of outreach, and understanding that while some of the larger companies are going to be challenges to knock the door of, it’s a grassroots movement. It’s the people behind this that really make this a viable objective. So, as far as plugging us, I’d say, come reach out if you guys are interested. If anybody has any custom projects or ideas that they want to see come to fruition, we’re available, Greentekplanet.com, and shop utensils, if people wanted to buy some of the products.

Jordan Hinshaw:

Our big push and our big reason for doing businesses is to impact disadvantaged communities. I came from one, the north side of Long Beach, and I understand that the waste ends up in these places, I understand that the jobs don’t go to these places, and that the community needs help. So, working with that, there’s a lot of community events, a lot of cleanups, a lot of food giveaways. We were doing some last week that… I just really want to be able to connect with the city on, and my team on. So, if there’s any questions, I’d definitely be open.

Matt Baum:

Cool. It sounds like you guys are doing it right. You’re buying American, you’re using American hemp, you’re repurposing waste hemp to do this stuff, you’re putting jobs in the community, this is the dream, right? This is what it’s all about. Let’s get-

Jordan Hinshaw:

Living the dream brother.

Matt Baum:

Yeah, let’s get behind this people, come on. I want to send huge, thanks to Jordan for coming on the show. I will have links to GreenTek Packaging in the show notes for this episode, so you can check out all the cool things they’re doing over there. Like he said, if you have custom needs and you want to work with hemp plastic, they are the company to contact. Now, not to get too political here, but listen to what he was saying about American jobs, and working in the community, and using American hemp, and keeping it all here without any need for petroleum, and other gnarly chemicals that are not only bad for the environment, but we even outsource from other countries. I can’t think of anything more American than what is going on in the hemp movement right now, with companies like GreenTek Packaging. I’m just happy they’re out there.

Matt Baum:

(Singing)

Matt Baum:

That’s about it for this episode. But again, I want to thank Canvas CBD for partnering with us. Don’t forget, go to Canvasrelief.com, use the code Friend15, for 15% off your purchase, and let them know that you want to help them, and you think it’s awesome that they are supporting ministryofhemp.com. Speaking of supporting ministryofhemp.com, if you like what we’re doing here, and you think that hemp can probably change the world, head overdue Patreon\ministryofhemp, and become a Ministry of Hemp insider. Any amount you give makes you an insider, and it gives you access to early articles, podcast extras, and all kinds of other stuff. But more than that, it helps us get the good word of hemp out to other people.

Matt Baum:

Also, leave us a star rating, or a written review on wherever you’re listening to the podcast. This show is available anywhere you can download podcasts, and your reviews and star ratings and thumbs up or whatever they have, it really helps put us in front of other listeners. But, we don’t just do it for listeners either. Here at the Ministry of Hemp, we believe that an accessible world is a better world for everyone. So, we have a full written transcript for this episode in the show notes, over at ministryofhemp.com. Speaking of ministryofhemp.com, don’t forget to check out our latest article on the best CBD pre-rolls of 2020 that I mentioned in the beginning of the show.

Matt Baum:

If that’s not enough, you can always find us on all our social medias, at Ministryofhemp\ministryofhemp. We’re always kicking out great links to quality companies, quality news stories, and good old hemp education. All right. It’s time for me to get out of here, and I like to end the show the same way every week. I like to say, remember to take care of yourself, take care of others and make good decisions will you? This is Matt Baum with the Ministry of Hemp, signing off.

On this episode of the Ministry of Hemp podcast, we’re confusing our neighbors and getting very relaxed as we try smoking our CBD, probably...

The Ministry of Hemp Podcast Episode 2: Eat Drink and Be Hempy In this episode, Matt looks at how to add hemp seeds to...

Third-party CBD testing is vital to ensure consumers receive safe, quality products. Research shows many CBD oil products are fake or mislabeled. In this...